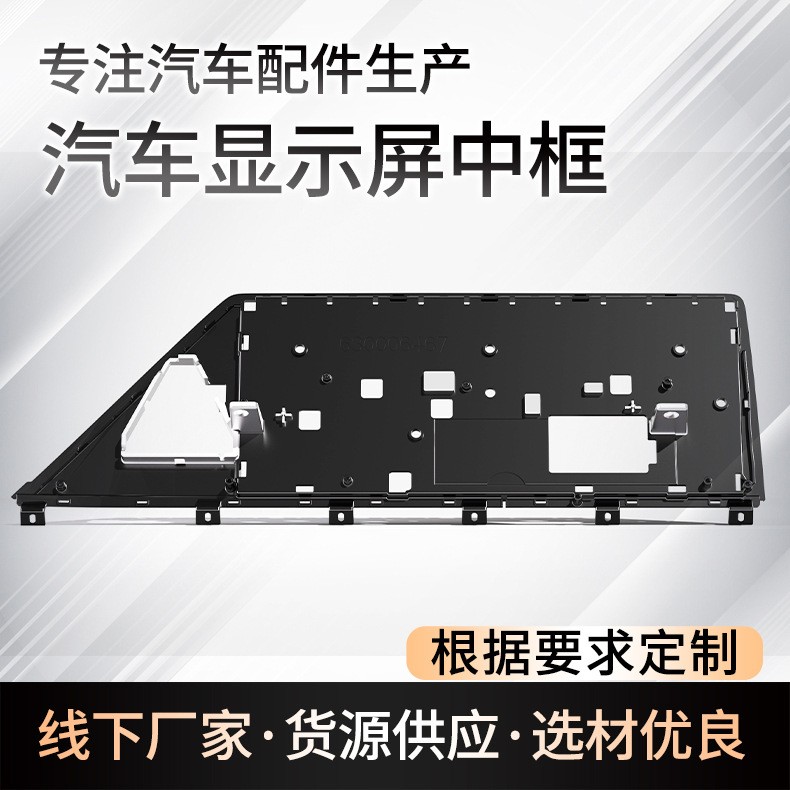

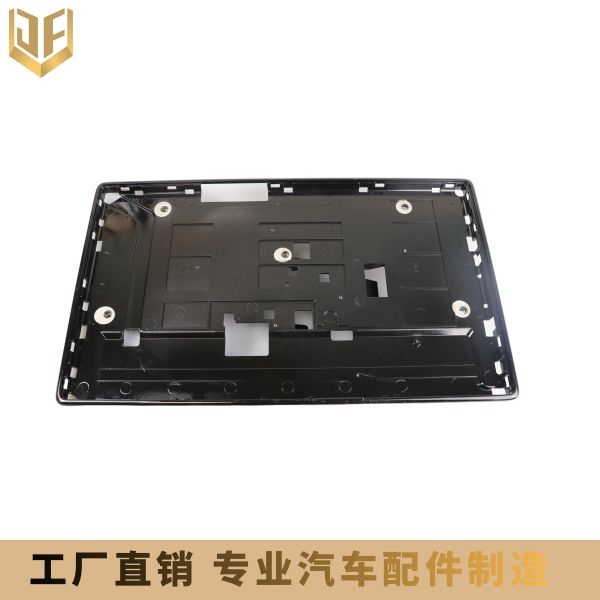

New Energy Vehicle Central Control Bracket, Precision Die Casting for Smart Automotive Interiors

Description

The central control bracket for new energy vehicles is a key structural component used to support the central display and navigation system. It requires high precision, strength, and surface quality to ensure both functionality and aesthetic performance inside the vehicle.

At Shenzhen Jinyuanfu Precision Manufacturing Co., Ltd., we specialize in high-strength aluminum and magnesium alloy die casting for automotive components. With advanced CNC machining and strict quality control systems, we ensure that every bracket meets the exacting standards of modern new energy vehicles.

Key Process Features

Material Selection

Lightweight, high-strength aluminum or magnesium alloys provide excellent mechanical properties, corrosion resistance, and durability—perfect for NEV applications.

Mold Design

Precision-designed molds ensure accurate shape, wall thickness, and cooling efficiency, reducing defects and improving dimensional stability.

Casting Process Control

Optimized parameters for injection speed, pressure, solidification, and cooling time guarantee consistent casting performance and minimize porosity or shrinkage.

Surface Treatment

A variety of finishing options are available, including deburring, polishing, sandblasting, electrophoretic coating, and anodizing, providing both visual appeal and long-term protection.

Dimensional Accuracy

Using CMM (Coordinate Measuring Machines) and precision machining, we ensure each bracket meets strict tolerance and assembly requirements.

Heat Treatment

For components with higher strength or hardness requirements, solution and aging treatments are applied to enhance performance.

Testing & Quality Assurance

Through X-ray inspection, ultrasonic testing, and tensile strength evaluation, each component is verified for internal integrity and mechanical strength.

Applications

Central display & navigation support bracket

Instrument panel mounting frame

EV battery housing

Motor casing & controller enclosure

Why Choose Jinyuanfu

IATF 16949 certified manufacturer

Advanced die casting & CNC machining equipment

Strict quality control and on-time delivery

Custom engineering support for NEV projects